Track work in progress let your operators report progress for each task.

Shop floor planning and control ppt.

Shop floor planning control the production environmentin f o r m a tio n e x c h a n g e b e t w e e n l e v e l 3 4 chapter4 3 4.

Shop status provides the added visibility necessary for staying on.

Assign jobs to your operators and track their progress in the plan in real time.

Iv vii unit iv shop floor control and introduction to fms prepared by manimaran m assistant professor k 2.

Shop floor planning and control is the process of using methods and tools to track schedule and report the status of work in progress wip manufacturing from your floor level giving you a clear channel.

Shop floor management 7 kanban a japanese inventory control system to control supply chain.

Shop floor planning control several generic tasks characterize production the.

Update in real time refresh your plan based on real time data from the shop floor.

Shop floor control provides shop personnel with a set of easy to use transactions for reporting work order operation completions and quantities of items produced.

Let them review and select their tasks.

Shop floor management is concerned with preplanning planning staffing directing monitoring and control of activities that enhance shop efficiency and analysis.

Lean it is a business philosophy that means executing things as simply and cheaply as possible while providing best quality and fast.

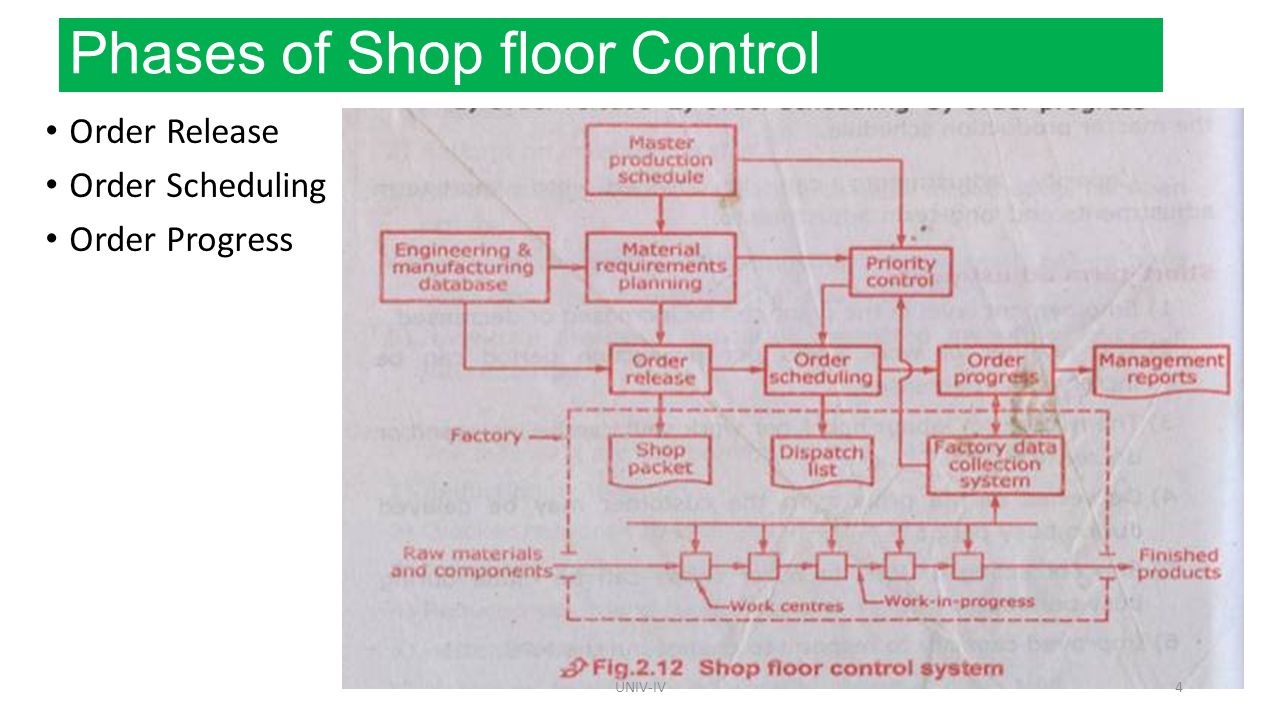

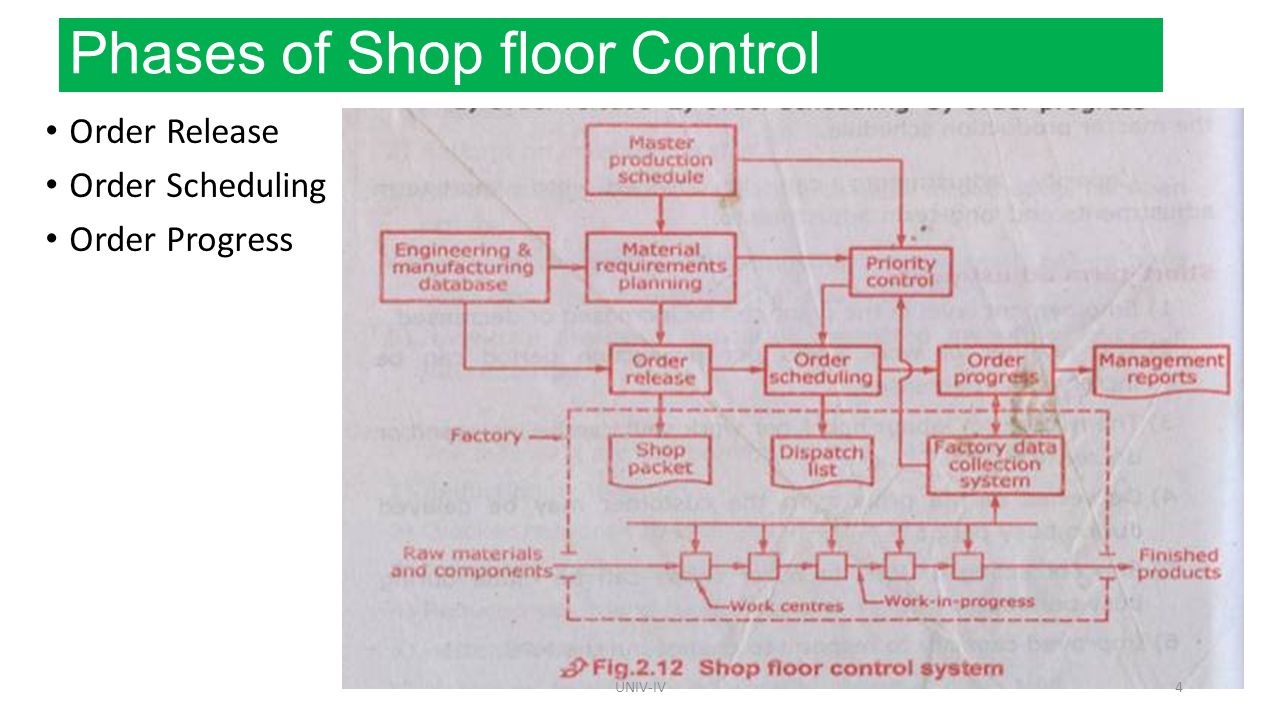

Unit iv shop floor control and introduction to fms shop floor control phases factory data collection system automatic identification methods bar code technology automated data collection system.

Advanced planning and scheduling aps for shop floor control.

Shop floor control is necessary for any manufacturing assembling or processing business.

Production operations activity signifies the process of transformation of materials inputs into desired output product services.

Me 2402 computer integrated manufacturing cim year semester.

Execute the plan assign jobs to operators.

However significant data and purposeful communication exchange can be used as an important management tool.

Thus shop floor management should not serve as a control instrument for the management but essentially to improve communication.

Shop floor control execute and monitor your plan on the shop floor.